X-ONE Resin BlueCast

€110.83 Tax excluded

NEW GENERATION X-ONE

NEW GENERATION OF CASTABLE RESINS

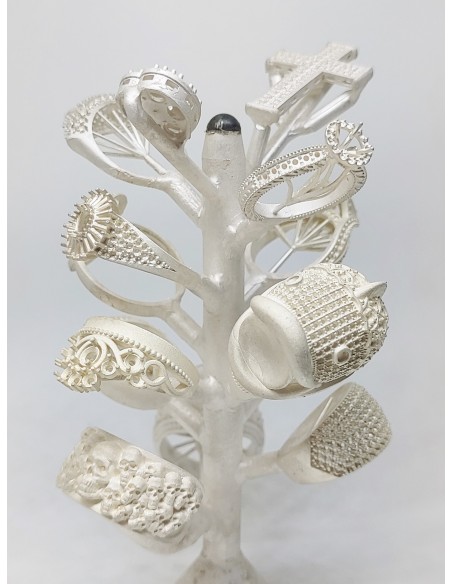

X-One® is the real meltable resin developed and produce by BlueCast® for DLP and Monochromatic LCD machines. Thanks to the low temperature melting polymer it ensures smooth surface finish and perfect lettering.

It was developed by BLueCast R&D in order to allow perfect casting results with any kind of investments and burnout cycles.

– ONE resin for ONE thousand applications

– The first castable resin developed for the new LCD monochromatic generation and DLP printers.

– Perfect casting results with any kind of investments and burnout cycles. Low temperature burnout compatibility (even if we recommend 750°C last stage, everything is burned out at 680°C).

– Extreme accuracy and exceptional detail without shrinkage.

– The first real meltable resin at low temperature.

– Excellent dimensional stability in time. No shrinkage (natural shrinkage will be compensated during print making polymer expand chemically).

– Strong adhesion to platform (adhesion layers are exposure layers x4 or even x3), no need to primer.

– You can choice for chemical postcuring (longer washing in alcohol make a chemical reaction with X-One) or for traditional washing and UV oven postcuring. After chemical postcuring the color resin change from dark green to gray/white to permit you to check if the procedure was correct

FILES:

Características BlueCast X-ONE

![BlueCast X10 – Sharpenizer [LCD/DLP]](https://www.3dprinters-shop.com/1765-home_default/bluecast-x10-sharpenizer-lcddlp-.jpg)